Soon after 1st January 2020 the bunker industry realised that the introduction of Very Low Sulphur Fuel Oil (VLSFO) was without major issues. What has changed, however, is that there is now an increased responsibility on the vessel’s crew for housekeeping and fuel treatment compared to a traditional HSFO.

The scope of ISO 8217 defines the requirements for fuels at delivery and prior onboard treatment. Marine fuel suppliers must deliver fuel that is fit for purpose, but it is down to the crew to ensure the fuel is fit for use. Although the scope is often overlooked, it puts responsibility on the vessel’s crew to ensure fuel treatment is performed in the best and most efficient way, ensuring the fuel is fit for use.

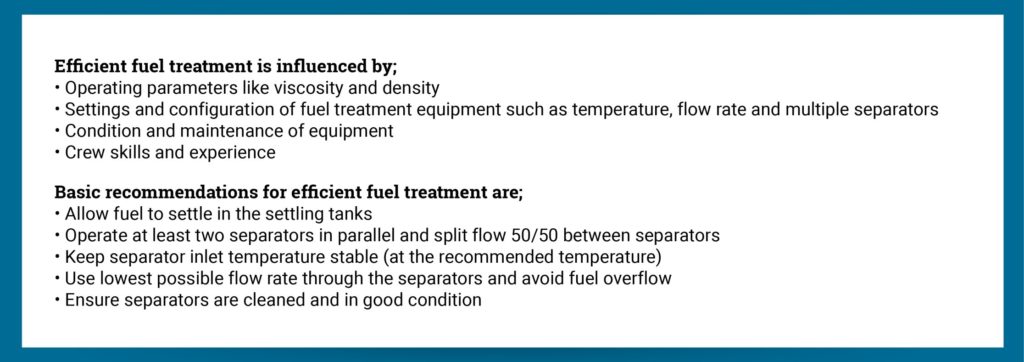

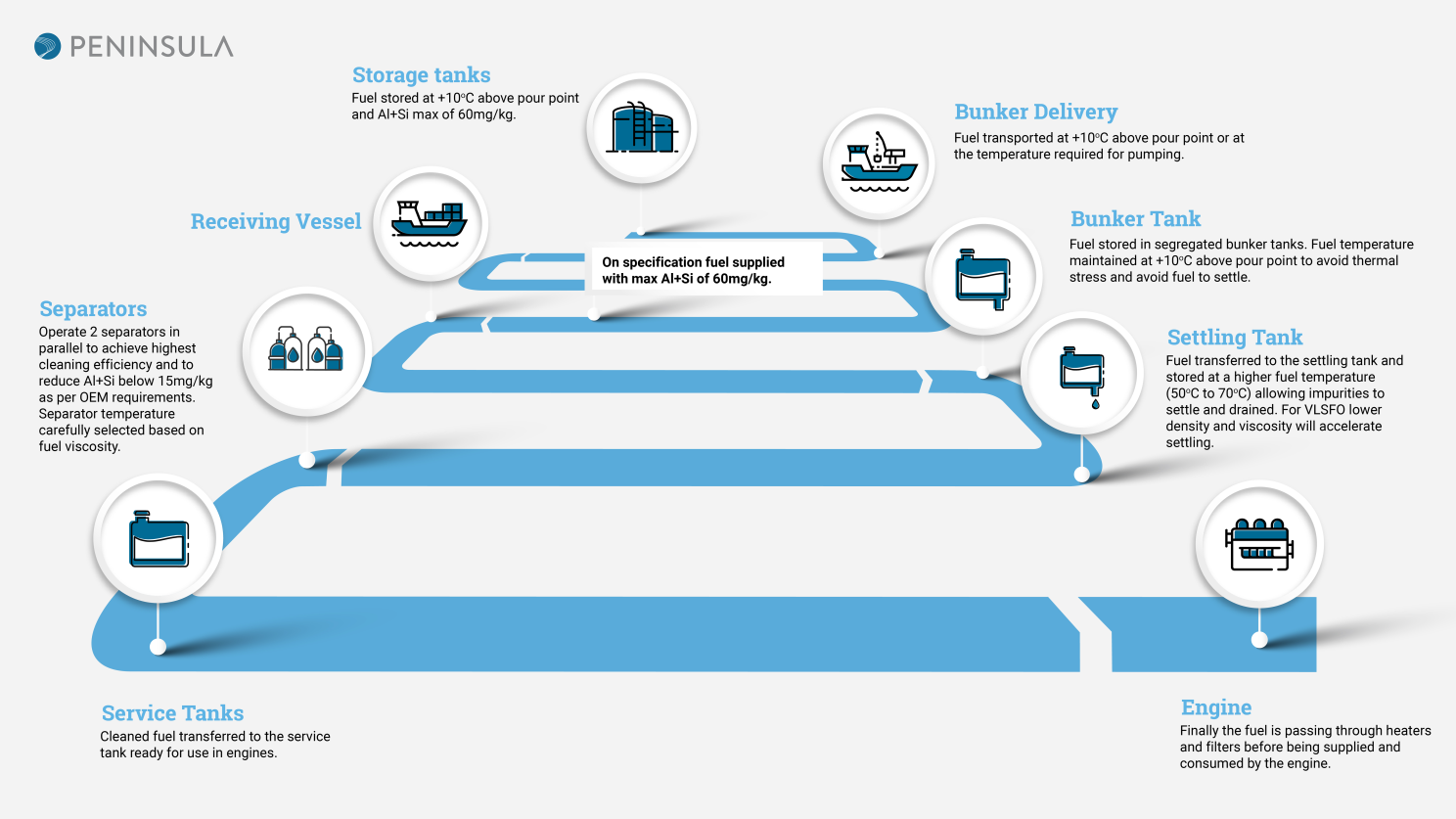

A good example is cat fines, also known as Aluminium + Silicon (Al+Si), which originate from the refinery process. ISO 8217 limits Al+Si at 60 mg/kg but the general recommendation is to reduce Al+Si to below 15 mg/kg before it enters the engine. In order for the fuel to meet the original equipment manufacturer’s (OEM’s) requirements, it has to be efficiently treated onboard by settling, centrifuging and filtering.

Separators systems, for example, have an efficiency of around 85% for Al+Si. This 85% efficiency can be achieved by operating two units in parallel. A single unit achieves efficiency of about 70%. Industry best practice is to parallel operate two units to achieve the best cleaning efficiency when Al+Si >25 mg/kg.

The positive attributes of VLSFO are that density and viscosity are generally lower and will therefore further increase fuel treatment efficiency given a lower density and viscosity means easier separation (Stokes Law).

Another integral aspect for onboard fuel handling and treatment is fuel temperature. Fuel temperature management is essential to avoid thermal stress on marine fuels. Storage tank temperatures should be 10°C above pour point, no more and no less. Also, the settling tank and service tank temperatures should be kept at the lowest temperature possible to avoid thermal stress.

Finally, and most importantly, the recommendation is to avoid the mixing of fuels and always keep fuels segregated. This isn’t new, as industry best practice has always been to avoid the mixing of fuels, however for VLSFO, it is even more essential. Avoiding mixing fuels will significantly reduce the risk of onboard issues.

Peninsula features a professional, in-house, quality team to ensure the products we deliver are suitable for customers. Our focus on customer centricity and solutions is why we are the benchmark for quality.